Product Types

Overpressure can result in devastating events, which is why Fike rupture discs have been trusted for more than 75 years to “burst” precisely when called upon to relieve pressure and protect workers and businesses from a potential disaster.

Fike offers numerous types of rupture discs to ensure the most reliable pressure relief solution in every application: vapor or liquid media, high or low pressures, hygienic requirements, and more.

Fike rupture discs are frequently used in the following sectors and processes:

- Pharmaceutical Manufacturing

- Aviation

- Oil and Gas

- Military and Defense

- Pressure Relief Valve Isolation

- Chemical Plant

- Aerospace and Satellite

- Food and Beverage Processing

Standard Forward

Disc Names

Poly-SD, SCRD, HOV, AD, P Series

Disc Category

Forward Acting

Function

Available in a range of materials and sizes and suitable for ambient to high pressures. Best solution for applications without the requirement of a minimum free vapor volume.

E-Catalog

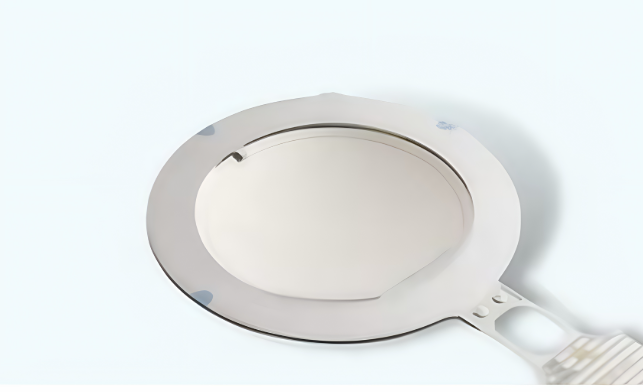

Fike’s proprietary G2 manufacturing technology results in reverse-acting rupture discs with the best operating ratios, burst tolerances, cycle life and backpressures available.

Allows production facilities to operate at full capacity without worrying about changing burst pressure. The opening feature is laser-machined or milled, thus providing ultra-reliable durability.

RD500 Atlas

Function

Offers burst pressures up to 1500 PSIG (103.42 BARG) and sizes up to 42″ while still featuring 95/100 (ASME/EN ISO 4126-2) percent operating ratio, liquid or vapor service, back-pressure resistance and unrivaled cycling capability.

Operating Ratio

95% of marked burst pressures over 40 psig (2.76 barg) – ASME

95% of minimum burst tolerance for burst pressures less than or equal to 40 psig (2.76 barg) – ASME and EN ISO 4126-2

100% of minimum burst pressure over 40 psig (2.76 barg) -EN ISO 4126-2

RD520 Axius

Function

Designed for use in the most challenging industrial pressure relief applications, the reverse-acting, problem-solving RD520 AXIUS rupture disc is available in a range of corrosion-resistant materials and has the tightest burst tolerances available.

Operating Ratio

95% of marked burst pressures over 40 psig (2.76 barg) – ASME

95% of minimum burst tolerance for burst pressures less than or equal to 40 psig (2.76 barg) – ASME and EN ISO 4126-2

100% of minimum burst pressure over 40 psig (2.76 barg) -EN ISO 4126-2

RD540 Ultra Düşük Basınç

Function

First high-performance metallic rupture disc for use in very low-pressure applications such as glass lined reactors. Ideal replacement for graphite rupture discs.

Operating Ratio

90% Operating Ratio

E-Catalog

Hygienic rupture discs must maintain similar hygienic qualities found in a manufacturing facility in the biotech, food, beverage and pharmaceutical industries. Unhygienic rupture discs and holders can collect unwanted residue or bacteria, which can lead to batch failure, production disruption and irreparable damage to customer confidence.

The rupture disc meets cleanliness standards and is designed to withstand the high burst pressures and temperatures generated by CIP/SIP equipment. It is manufactured using a mild acid and low voltage electricity to create an ultra-smooth surface that greatly reduces areas within the media where bacteria can collect.

It can be used safely in areas such as Biotechnology, Beverage Processing, Pharmaceutical Industry, Food Processing.

Premium Hygienic

Disc Names

Axius® SC, RD540 SC

Disc Category

Reverse Acting, Hygienic

Function

Free of any indentations or crevices which may trap process contaminants and designed with CIP/SIP functionality makes Axius® SC and RD540 SC ideal for bio-tech, pharmaceutical and food and beverage applications.

Some pressure relief challenges fall outside of what is considered “standard.” With an experienced team of pressure relief experts, an on-site ASME certified flow characteristics lab, and more experience than anyone else in the industry, Fike can custom-solve all of your unique pressure-related challenges.

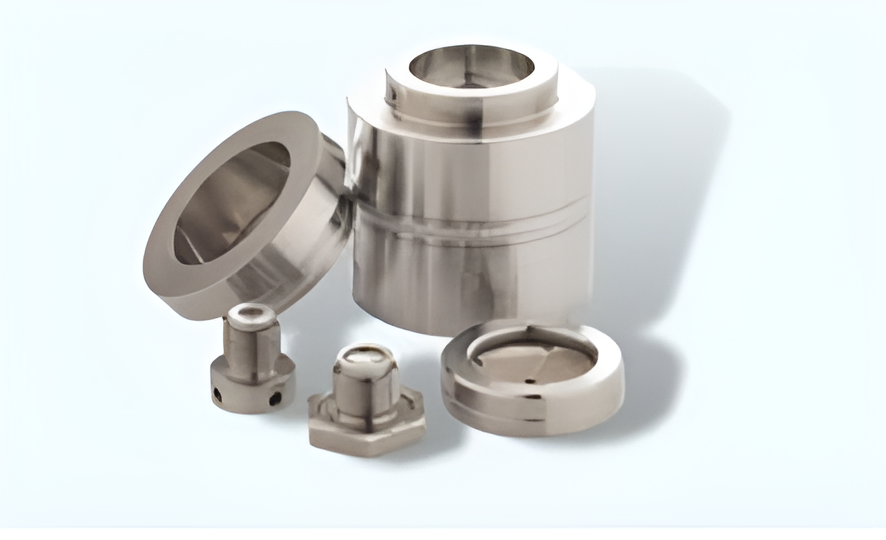

Specialty

Disc Category

Custom Engineered, Extruder

Function

Available for applications where Fike standard rupture discs and holders require modifications or complete re-engineering to meet your unique needs.

Communication