Product Types

Foam extinguishing systems are used to limit fire damage in many challenging and high-risk applications.

Foam water systems are designed to distribute foam water solution to a specific hazard area within a protected space.

The type and potential size of the hazard determine the number of discharge devices, the type of foam concentrate, and the foam water discharge rate and duration.

The system also requires appropriate discharge devices to control and/or extinguish most Class A and Class B fires. The piping system is connected to a water source through a control valve (wet, dry, deluge, pre-action, flow control) activated by the operation of automatic detection equipment mounted in the same areas as the discharge devices.

Frequently used areas:

- Chemical industry

- Refineries

- Power plants

- Waste incineration plants

- Logistics halls with high plastic content

- Aircraft maintenance halls

- Hangars

- Helicopter landing pads

- Offshore platforms and ships

- Tire storage areas

- Coal silos

- Pipeline pump stations

- Mineral oil tanks including collection containers

- Areas where there is a risk of leakage of flammable liquids.

Classification According to Foam Expansion Rates

Low Expansion Foam Systems

Foam Expansion Rate <20:1

In low expansion, the volume of the finished foam is less than or equal to 20 times the volume of the pre-mixed solution used to produce it.

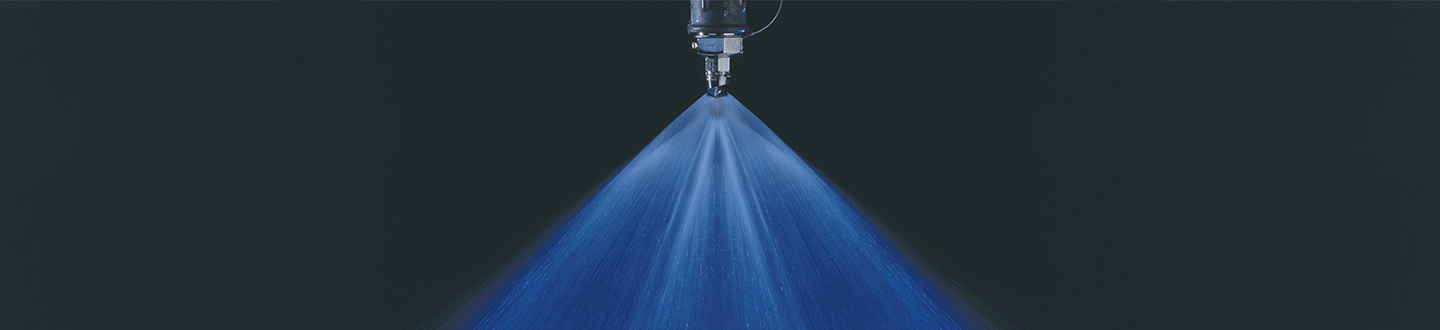

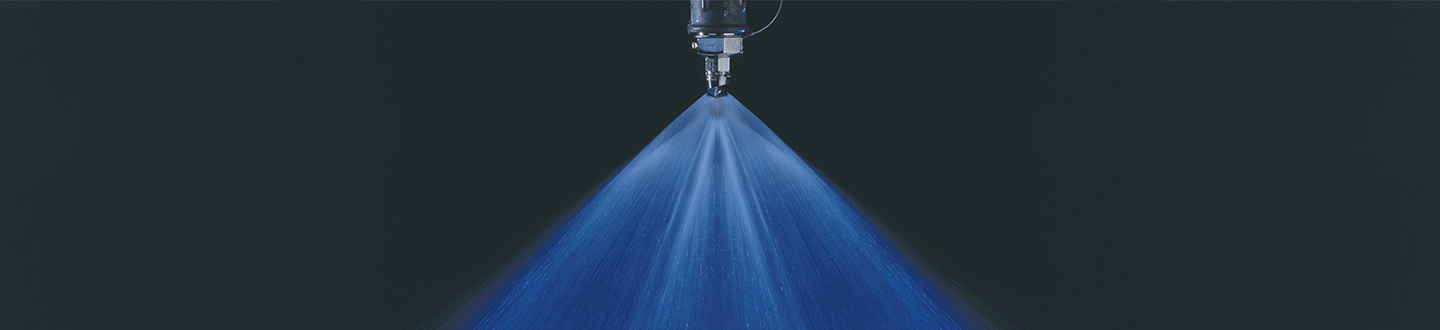

The bubbles in low expansion are very small, dense, and heavy. Expansion is closely related to the type of foam concentrate and the nozzle and foam discharge device used. Strong foam density allows for long projection distances and heights with the help of nozzles or monitors in fixed/mobile foam discharge devices. Firefighters can work from a safe distance. Low expansion foam has good spreading properties over fuel surfaces and makes vapors impermeable.

Low expansion foam applications are relatively less affected by atmospheric conditions such as wind and rain compared to other expansion types. The foam is stable and provides a strong coating. A high water ratio provides significant additional cooling.

The foam is lighter than flammable materials such as oil or gasoline, and as a result, it creates a stable foam blanket that insulates against oxygen and reduces heat radiation. This effectively extinguishes fires caused by hydrocarbons, polar solvents, or mixtures.

Low expansion foams generally find a wide range of applications in tank storage, refineries, airports, wastewater treatment plants, manufacturing facilities, storage facilities, and marinas.

Medium Expansion Foam Systems

Foam Expansion Ratio 20:1 ≤ x < 200:1

Medium expansion foam can provide quick and effective protection for flammable liquid spill fires or some toxic liquid spills where rapid vapor suppression is necessary. It is effective in both indoor and outdoor environments.

It is mostly used by municipal fire departments for small surfaces such as roadway traffic accidents or to control spills of hazardous chemicals.

Compared to low expansion foams, a large amount of finished foam is produced in a short time with a minimum amount of pre-mixed solution. The thick foam blanket quickly spreads over the fuel, separating the fuel from the oxygen source and causing the fire to extinguish. The water it contains provides additional cooling effects to control the fire more quickly and prevent re-ignition. Being of low density makes medium expansion foam somewhat sensitive to wind and adverse weather conditions compared to low expansion foam.

High Expansion Foam Systems

Foam Expansion Ratio ≥ 200:1

High expansion foam can achieve expansion ratios of 1:1000 with the combined use of high expansion foam generators or equipment. In this method, a small amount of water is used to ensure the large discharge of high expansion finished foam. The air bubbles formed in high expansion are light and are not very suitable for outdoor use.

High expansion foam production is used to fill large volume sections in three-dimensional fires. The areas of use for high expansion foam systems: aircraft hangars, warehouses, ship engine rooms, etc.

Classification According to System Types

Classifications made according to the system type are defined by the characteristics of the valve station to be used within the system. In addition to the fire valve station used, it operates with the combined use of a foam storage tank, foam proportioner, hydraulic concentration valve, and application devices that provide the discharge of the generated foam-water solution.

These system classifications are as follows:

Wet Alarm Valve System

Dry Alarm Valve and Pre-action Systems

Instead of storing water, the pipes of a dry pipe sprinkler system are filled with compressed air or nitrogen, which keeps the main valve in the closed position. In areas subject to freezing temperatures, systems with dry alarm valves are recommended for reliable automatic fire protection.

These systems work as in standard dry pipe and pre-action sprinkler installations, in addition to this, when the sprinkler head is activated, the air in the pipeline is first discharged and then the foam hydraulic concentration valve located on the foam tank is hydraulically triggered. In this way, the foam concentrate waiting behind the hydraulic concentration valve is ensured to flow to the foam proportioner. The foam-water solution created in the proportioner is sent to the system.

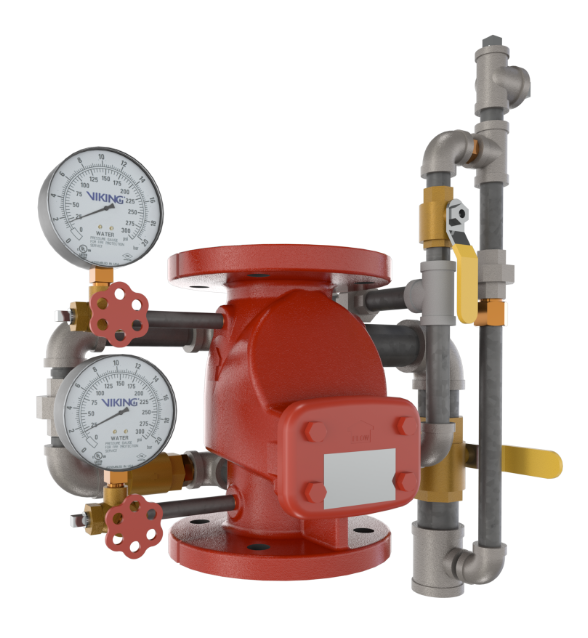

Deluge Valve Systems

The Deluge Valve Foam System is a fixed fire protection system that completely floods an area with foam solution through a system of piping and open nozzles or other discharge devices. The system piping is empty until the deluge valve is activated by a hydraulic, pneumatic, electric or manual release system.

Deluge Valve Foam Water Systems are used to control and/or extinguish fires that require smothering and cooling agents. For example: extraction facilities, aircraft hangars and areas where flammable-liquid leakage fires may occur, etc.

The deluge valve is held closed by a pressurized upper valve chamber. Pressure is maintained by a restriction on the service side. This upper chamber is also connected to the discharge line. When pressure is released from the upper chamber through the discharge line, the valve is lifted by the water pressure below the valve. Water floods the system and sounds the alarm.

Communication